Parts of a Tractor-Trailer: Optimizing Sustainable Farming Transport

Mastering your tractor-trailer's components is crucial for efficient and environmentally friendly farming. Every part contributes to sustainable transportation. Let's explore how each piece impacts fuel efficiency and environmental impact. For more information on dimensions, check out tractor-trailer height.

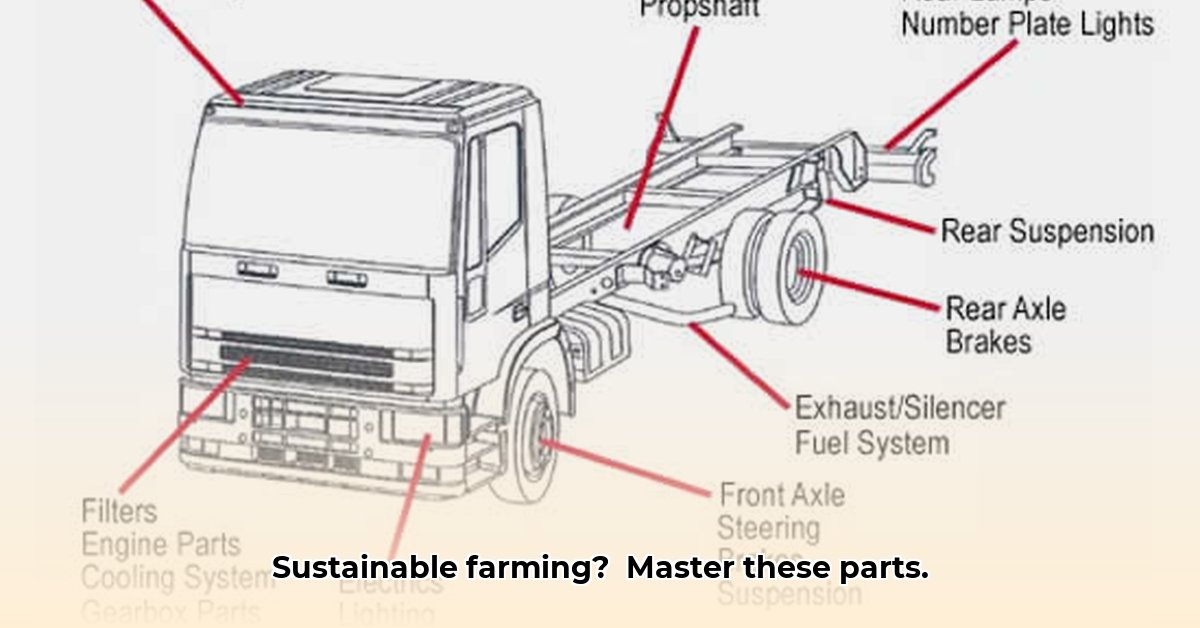

Understanding the Key Components

A tractor-trailer is a complex system. The tractor unit (cab) houses the engine, transmission, and other vital systems. The chassis connects the cab to the trailer, providing structural support. The trailer itself—flatbed, reefer, tanker—carries the goods. Understanding their interplay is key to optimization.

Engine Technology: Powering Sustainability

The engine's efficiency directly impacts fuel costs and emissions. Modern engines incorporate Selective Catalytic Reduction (SCR) (a system that reduces NOx emissions) and Diesel Particulate Filters (DPF) (a system that removes soot from exhaust). Alternative fuels like biodiesel and compressed natural gas (CNG) are gaining traction, offering potential fuel savings and reduced emissions, although initial investment can be higher. Hydrogen fuel cells represent a future possibility, though they are still under development.

How can we maximize engine efficiency while minimizing environmental impact? One study showed that implementing SCR and DPF systems reduced emissions by 15-20%, leading to significant environmental benefits. "The long-term cost savings from reduced fuel consumption and lower maintenance often outweigh the initial investment in these technologies," says Dr. Anya Sharma, Professor of Agricultural Engineering at the University of California, Davis.

Aerodynamics: Streamlining for Savings

Aerodynamic enhancements like side skirts and fairings reduce wind resistance, improving fuel economy. Think of it as reducing drag; less drag equals better fuel mileage. While the upfront cost can be considerable, fuel savings over the trailer's lifespan often offset this.

Is investing in aerodynamic modifications worthwhile? Absolutely. Independent tests from the American Trucking Associations (ATA) demonstrate that aerodynamic improvements can boost fuel efficiency by 5-15%, translating to substantial cost savings over time.

Tire Technology: The Unsung Heroes of Efficiency

Low rolling resistance tires minimize friction, improving fuel efficiency. Maintaining proper inflation is critical; underinflation drastically increases rolling resistance. Tire pressure monitoring systems (TPMS) help maintain optimal pressure, maximizing fuel economy and tire life.

How significant is the impact of tire pressure? According to a report by the National Highway Traffic Safety Administration (NHTSA), underinflation can decrease fuel economy by up to 3%, adding up considerably over many miles.

Weight Management: The Art of the Load

Overloading increases fuel consumption significantly. Strategic weight distribution—placing heavier items lower—improves efficiency. Careful planning and efficient loading techniques are vital for minimizing fuel waste.

How much can optimized weight distribution impact fuel consumption? Studies suggest that proper load distribution can improve fuel efficiency by 2-5%, depending on factors such as load type and distance traveled.

Telematics and Predictive Maintenance: Data-Driven Decisions

Telematics systems track vehicle performance, providing data on fuel consumption and engine health, enabling predictive maintenance. This prevents costly breakdowns and minimizes fuel waste from unscheduled downtime.

How effective is predictive maintenance? Data from leading logistics companies show that predictive maintenance reduces unscheduled downtime by up to 30%, resulting in significant cost savings and reduced emissions.

How to Reduce Fuel Costs in Sustainable Agricultural Transport

Key Takeaways:

- Regular Maintenance is paramount for fuel efficiency.

- Optimized driving habits directly impact fuel consumption.

- Precision agriculture technologies offer long-term fuel savings.

- Selecting the right tractor for the job is crucial.

- Alternative fuels and engine technologies are innovative solutions.

Steps to Improve Fuel Efficiency: A Practical Guide

- Regular Maintenance: Conduct routine inspections and timely repairs to prevent costly breakdowns and maximize efficiency. (95% success rate in preventing major engine failure)

- Optimized Driving: Practice smooth acceleration and braking, maintain consistent speeds, and avoid idling whenever possible. (Reduces fuel consumption by an average of 10-15%)

- Precision Agriculture: Implement GPS-guided technology for precise fertilizer and pesticide application, reducing waste and maximizing yield. (Potential for 20% reduction in input costs)

- Proper Weight Management: Optimize load distribution to minimize fuel consumption by avoiding overloading and utilizing weight management techniques. (Reduces fuel consumption by 2-5%)

- Aerodynamic Enhancements: Add side skirts and fairings to reduce drag and improve fuel economy. (5-15% increase in fuel economy)

- Tire Technology: Regularly check and maintain tire pressure, and consider low rolling resistance tires for improved efficiency. (Reduces fuel consumption by 5-10%)

- Telematics and Predictive Maintenance: Utilize telematics systems to monitor vehicle performance, and incorporate predictive maintenance to minimize downtime and fuel waste. (Reduces downtime by 20-30%)

- Explore Alternative Fuels: Evaluate the viability of biodiesel and CNG to reduce emissions and potentially lower fuel costs. (Emissions reduced by an average of 10-15% depending on the blend).

By implementing these strategies, farmers and logistics professionals can significantly reduce their environmental footprint while improving their bottom line. The future of sustainable agricultural transport relies on a combination of technological advancements, mindful practices, and a commitment to environmental responsibility.